Don't miss our holiday offer - 30% OFF!

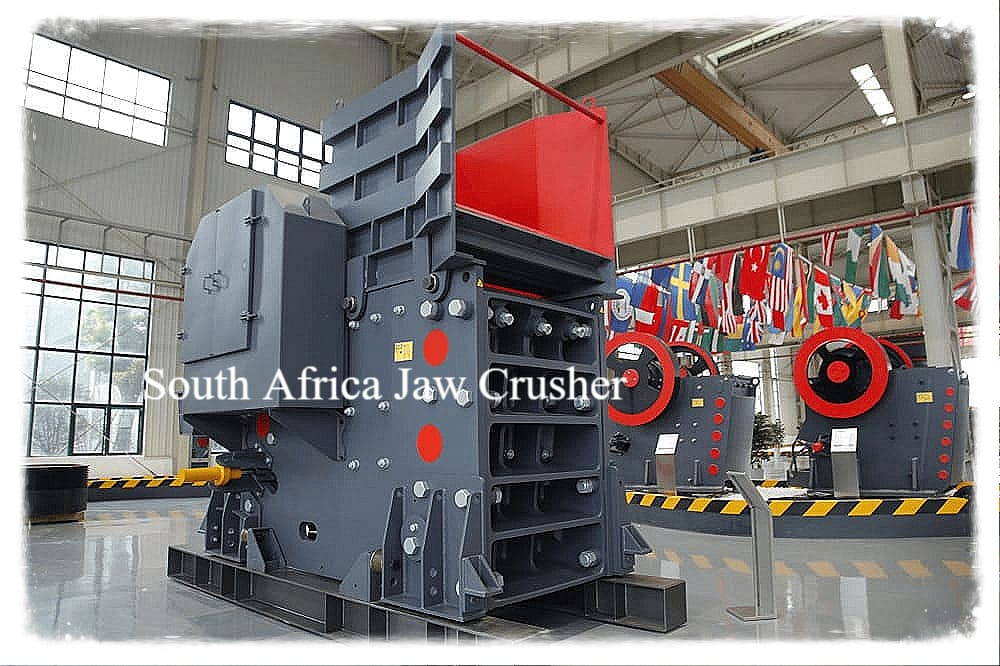

Jaw Crusher and the South African Market

South Africa’s jaw crusher market is driven by robust demand from its mining and construction sectors, key pillars of the economy. With abundant mineral resources like gold, platinum, and diamonds, the country relies heavily on efficient crushing equipment to process raw materials. The construction industry, fueled by infrastructure projects, further amplifies the need for reliable jaw crushers. Market trends indicate a growing preference for high-capacity, durable, and energy-efficient machines to meet large-scale production demands.

Jaw crushers are essential for primary crushing, breaking down large rocks into manageable sizes for further processing. In mining, they handle tough, abrasive ores, ensuring high throughput and minimal downtime. In construction, they process aggregates for roads, buildings, and bridges, supporting South Africa’s urban and infrastructural growth. Their versatility also extends to quarrying and recycling, making them indispensable across multiple industries.

Zenith, a globally recognized manufacturer, specializes in advanced crushing and grinding solutions. With decades of expertise, Zenith delivers innovative, high-performance equipment tailored to diverse industrial needs. Its jaw crushers, including the C6X and PE Series, are renowned for durability, efficiency, and adaptability, making them ideal for South Africa’s challenging operational environments. Zenith’s commitment to quality and local support positions it as a trusted partner in the region.

Overview of Jaw Crushers

Jaw crushers are robust machines designed for primary crushing, reducing large rocks or ores into smaller, manageable sizes. They operate by compressing material between a fixed and a movable jaw, driven by an eccentric shaft. This mechanical action ensures efficient crushing of hard and abrasive materials, with adjustable output sizes to meet specific requirements. Their simple yet effective design makes them a cornerstone of material processing.

In South Africa, jaw crushers are vital across multiple sectors. In mining, they process ores like gold, platinum, and coal, supporting the country’s position as a global mineral powerhouse. In metallurgy, they crush raw materials for smelting and refining processes. The construction industry relies on jaw crushers to produce aggregates for roads, bridges, and buildings, driven by ongoing infrastructure projects. Additionally, they are used in quarrying for stone production and in recycling for processing concrete and asphalt.

Zenith’s Jaw Crusher Products

C6X Series Jaw Crusher

- Description and Key Features: The C6X Series Jaw Crusher is Zenith’s flagship model, designed for high efficiency and productivity in demanding applications. It boasts energy efficiency through optimized motor performance, a high crushing ratio for superior output, and an advanced kinematic design that enhances crushing force while reducing wear. Its robust structure ensures stability under heavy loads.

- Technical Specifications:

- Max input size: Up to 1200mm, suitable for large raw materials.

- Min output size: Adjustable down to 60mm for precise product sizing.

- Capacity: Up to 1500 tons/hour, ideal for large-scale operations.

- Power range: 75-400 kW, depending on the model.

- Innovations: Features an integrated motor base for reduced vibration and easier installation, a hydraulic adjustment system for quick gap setting, and high-quality casting components for enhanced durability. The modular design simplifies maintenance and upgrades.

- Benefits for South African Users: The C6X Series excels in South Africa’s abrasive mining environments, offering reduced maintenance costs due to durable components. Its high durability handles tough materials like granite and iron ore, while the fast installation process minimizes downtime, critical for large-scale projects.

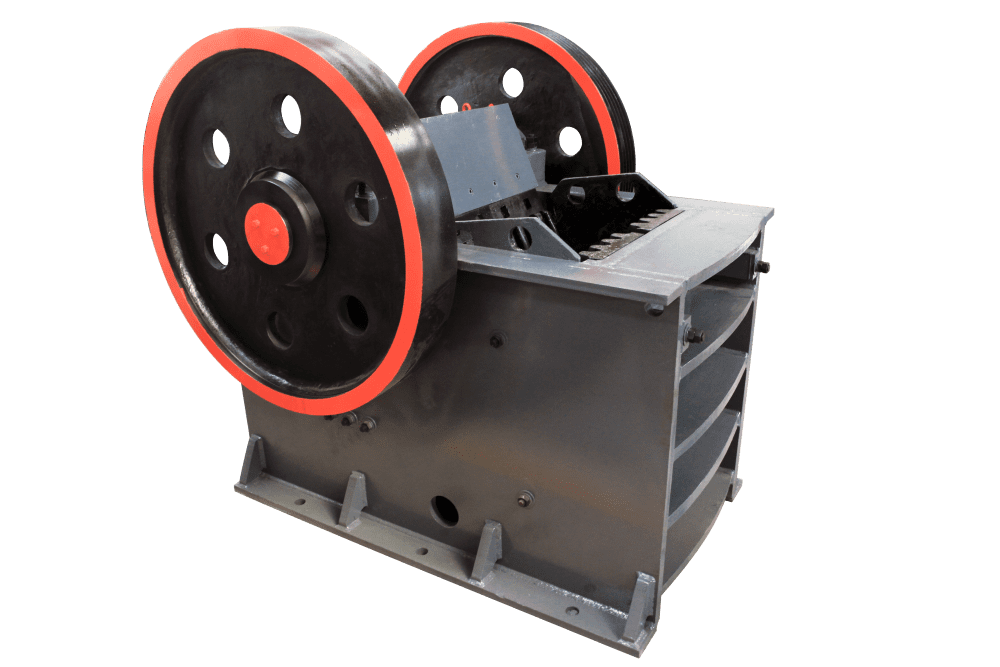

PE Series Jaw Crusher

- Description and Historical Significance: The PE Series Jaw Crusher is a classic, time-tested model renowned for its reliability as a primary crusher. Introduced decades ago, it remains a staple in Zenith’s lineup due to its proven performance in various industries worldwide.

- Technical Specifications:

- Available in 6 models (e.g., PE-250×400 to PE-1200×1500).

- Capacity range: 5-800 tons/hour, catering to both primary and secondary crushing.

- Max input size: Up to 1020mm; min output size: 20mm.

- Power range: 15-185 kW, depending on model.

- Features: Mimics animal jaw movement for efficient crushing, equipped with high manganese steel jaw plates for wear resistance, and a simple structure for easy operation. The deep crushing chamber enhances throughput.

- Suitability for Small to Medium-Scale Operations in South Africa: The PE Series is ideal for smaller quarries, construction sites, and medium-scale mining operations in South Africa. Its cost-effective design and lower initial investment make it accessible for businesses with moderate production needs, while its robust construction ensures reliability in rugged conditions.

Advantages of Zenith Jaw Crushers in South Africa

High Efficiency and Low Operating Costs

Zenith jaw crushers, such as the C6X and PE Series, are engineered for high efficiency, delivering superior crushing performance with minimal energy consumption. Their optimized designs ensure a high throughput, reducing the need for multiple machines. Low operating costs are achieved through durable components that minimize wear and tear, coupled with easy maintenance features like hydraulic adjustments, which save time and labor, making them cost-effective for South African operations.

Adaptability to Diverse Applications (Mining, Infrastructure, Quarrying)

Zenith jaw crushers are versatile, catering to South Africa’s varied industrial needs. In mining, they process abrasive ores like gold and platinum with ease. For infrastructure projects, they produce high-quality aggregates for roads and buildings. In quarrying, their adjustable output sizes support the production of diverse stone products. The C6X Series excels in large-scale tasks, while the PE Series suits smaller operations, ensuring flexibility across applications.

Local Support: Zenith’s Global Network and Service Availability in South Africa

Zenith’s global network ensures robust local support in South Africa, with access to spare parts, technical expertise, and after-sales service. Through regional distributors and service centers, Zenith provides prompt maintenance and training, minimizing operational disruptions. This localized presence enhances customer confidence, ensuring equipment reliability and longevity in South Africa’s demanding environments.

Environmental Considerations: Energy-Efficient Designs and Reduced Downtime

Zenith prioritizes sustainability with energy-efficient designs that lower power consumption, aligning with South Africa’s push for greener industrial practices. Features like optimized motor performance and advanced kinematics reduce energy waste. Additionally, the crushers’ high reliability and quick maintenance features minimize downtime, ensuring consistent production while reducing fuel and resource use, contributing to environmentally responsible operations.

Case Studies and Applications

Examples of Zenith Jaw Crushers in South African Projects

- Mining Project in Limpopo: A major gold mining operation in Limpopo utilized Zenith’s C6X Series Jaw Crusher to process high-grade gold ore. The crusher’s high crushing ratio and capacity of up to 1200 tons/hour enabled the mine to increase throughput by 25%, handling abrasive materials efficiently.

- Road Construction in Gauteng: A road infrastructure project in Gauteng employed Zenith’s PE Series Jaw Crusher (PE-600×900 model) to produce aggregates for highway construction. Its ability to handle diverse input sizes and deliver consistent output supported timely project completion.

- Quarrying in Western Cape: A medium-scale quarry used the PE Series Jaw Crusher for limestone processing, benefiting from its compact design and low maintenance, ideal for smaller operations.

Success Stories: Improved Productivity and Cost Savings for Customers

- Productivity Gains in Mining: The Limpopo gold mine reported a 30% reduction in processing time due to the C6X Series’ advanced kinematic design, which minimized blockages and enhanced material flow. This led to a significant boost in daily output.

- Cost Savings in Construction: The Gauteng road project achieved a 20% reduction in operational costs by using the PE Series’ durable manganese steel jaw plates, which extended component lifespan and reduced replacement frequency.

- Quarrying Efficiency: The Western Cape quarry saved approximately ZAR 500,000 annually in maintenance costs due to the PE Series’ simple structure and reliable performance, allowing for uninterrupted production cycles.

Testimonials or Feedback from South African Users

- Mining Manager, Limpopo: “Zenith’s C6X Jaw Crusher transformed our operations. Its durability and high capacity have made it a game-changer for processing tough ores, and the local support team ensured seamless installation.”

- Construction Contractor, Gauteng: “The PE Series crusher was perfect for our road project. It’s reliable, easy to maintain, and helped us stay on budget and schedule.”

- Quarry Owner, Western Cape: “We chose Zenith for its reputation, and the PE crusher exceeded expectations. It’s cost-effective and handles our limestone with ease, saving us significant downtime.”

In conclusion, Zenith’s C6X and PE Series jaw crushers are ideally suited for South Africa’s mining, construction, and quarrying sectors, offering high efficiency, durability, and adaptability to diverse applications. The C6X excels in large-scale operations with its advanced design, while the PE Series is perfect for smaller projects, both addressing local challenges like abrasive materials and high production demands. Zenith invites readers to contact their team for tailored crushing solutions, backed by a commitment to quality, innovation, and robust local support to meet South Africa’s unique market needs.