Don't miss our holiday offer - 30% OFF!

How is Iron Ore Mined? Complete Guide + Crusher Solutions

Introduction

Iron ore remains the backbone of modern industry, primarily fueling steel production for infrastructure, vehicles, and renewable energy systems like wind turbines. Nearly 98% of mined iron ore goes toward steelmaking, which supports global construction and manufacturing.

In 2024, global crude steel production dipped 1% to around 1.88 billion metric tons, with China’s output falling 1.7%. Projections for 2025 indicate stabilization near 1.85-1.9 billion tons, driven by Asia’s urbanization and green steel initiatives. Seaborne iron ore trade continues to surge, with major producers like Australia and Brazil supplying over half the world’s needs.

The market’s value hit $290.25 billion in 2024 and is forecast to reach $398 billion by 2032, highlighting iron ore’s economic dominance. Yet, an anticipated oversupply of 20-30 million tons in 2025—fueled by weak Chinese demand—intensifies the need for efficient extraction.

Efficient mining and processing are crucial for sustainable supply amid these pressures. Traditional methods often deplete water, emit dust, and harm ecosystems, clashing with regulations and net-zero goals.

Zenith leads with innovative equipment for iron ore operations. Our jaw crushers, cone crushers, and mills cut energy use by up to 30% and boost throughput, enabling greener workflows from pit to plant.

Overview of Iron Ore Mining Methods

Iron ore mining primarily relies on two main techniques: surface and underground methods. These approaches are chosen based on deposit depth, ore grade, and economic factors. Globally, over 95% of iron ore production comes from surface mining, reflecting its cost-effectiveness for large, shallow deposits.

Surface Mining (Open-Pit)

Surface mining, or open-pit mining, dominates iron ore extraction worldwide. It involves removing overlying soil and rock—known as overburden—to access the ore body. Massive excavators, haul trucks, and drills enable the recovery of vast quantities, often exceeding 100 million tons annually per major site.

This method suits deposits within 100-200 meters of the surface, as seen in Australia’s Pilbara region. Operations strip away layers in benches, using controlled blasting for fragmentation. It’s efficient but requires careful land rehabilitation to mitigate erosion and habitat loss.

| Mining Method | Depth Suitability | Pros | Cons | Zenith Solution |

|---|---|---|---|---|

| Open-Pit | <200m | High volume | Land disruption | Mobile Jaw Crushers |

| Underground | >300m | Selective | Higher cost | Cone Crushers |

Underground Mining

Underground mining targets deeper deposits, typically beyond 300 meters. Techniques include sublevel caving or room-and-pillar, where tunnels and shafts provide access. Sweden’s Kiruna mine, the world’s largest underground iron ore operation, exemplifies this, producing over 27 million tons yearly through automated systems.

Safety is paramount here, with ventilation and rock support preventing collapses. While more selective—recovering up to 90% of ore—it incurs higher costs due to labor and infrastructure. Only about 5% of global iron ore uses this method, mainly in high-grade European sites.

Global Trends

The iron ore mining landscape is evolving toward sustainability and automation by 2025. Oversupply risks, projected at 20-30 million tons amid China’s slowing steel demand, push operators to optimize yields. Innovations like autonomous haul trucks now operate in over 60% of open-pit sites, boosting efficiency by 20-30%.

Eco-friendly shifts include water recycling in 60% of surface operations and low-emission drilling. Zenith supports these trends with mobile crusher that integrate seamlessly into both surface and underground setups, reducing downtime and enhancing adaptability.

The Extraction and Initial Processing Stages

Once the mining method is selected, extraction begins with precise fragmentation and transport. These initial stages ensure ore is broken down and moved efficiently to processing facilities, minimizing bottlenecks.

In the iron ore extraction techniques of 2025, primary crushing is key to handling abrasive materials efficiently.

Drilling and Blasting

Drilling creates precise holes in the rock face, typically 100-300 mm in diameter, using rotary or percussive rigs. Explosives like ANFO are then loaded and detonated to fragment the ore into manageable pieces, often 0.5-1 meter in size.

This process is vital for open-pit operations, where patterns are optimized via software to reduce overbreak. By 2025, smart blasting systems cut ground vibration by up to 40%, improving environmental compliance. Autonomous drilling rigs now deliver 85% greater accuracy, speeding up cycles in iron ore sites.

Loading and Hauling

Post-blast, loaders like hydraulic shovels scoop fragmented ore into haul trucks with capacities up to 400 tons. These vehicles transport material to crushers or stockpiles, often covering distances of 2-5 km in open pits.

Efficiency hinges on fleet management and route optimization. In 2025, automated haulage systems boost transport efficiency by 30%, with over 60% of open-pit mines adopting autonomous trucks for safer, round-the-clock operations. This reduces fuel use and idling, aligning with sustainability targets.

Primary Crushing

Primary crushing reduces blasted ore from boulders up to 1.5 meters to a uniform size of 100-300 mm, enabling downstream processing. Stationary or semi-mobile units handle high volumes in harsh conditions, focusing on high throughput and low wear.

Zenith Jaw Crushers (e.g., PE Series) lead here, with capacities up to 1000 TPH and robust frames for abrasive iron ore. Their simple structure ensures reliable performance, with feed sizes up to 1200 mm and easy maintenance.

Beneficiation: Turning Raw Ore into Usable Concentrate

Beneficiation transforms low-grade iron ore into high-purity concentrate, essential for efficient steelmaking. This multi-stage process—crushing, screening, grinding, and separation—removes impurities like silica and alumina, boosting iron content from 30-40% to over 65%. In 2025, amid rising energy costs and sustainability mandates, innovations emphasize water recycling and low-emission tech, potentially slashing beneficiation energy use by 20-30% through advanced equipment. These upgrades align with global trends toward greener processing, as seen in modern magnetite plants.

Secondary and Tertiary Crushing

After primary crushing, secondary and tertiary stages further reduce ore to 10-50 mm, liberating valuable minerals from waste rock. Cone crushers excel here, applying pressure via a rotating mantle for uniform output.

Zenith HPT Series Cone Crushers offer precise control with large crushing ratios and high efficiency, ideal for iron ore circuits. Their low energy consumption can reduce power needs by up to 30%, while delivering uniform sizes for downstream flows. Built for durability in abrasive environments, these units handle feeds up to 300 mm.

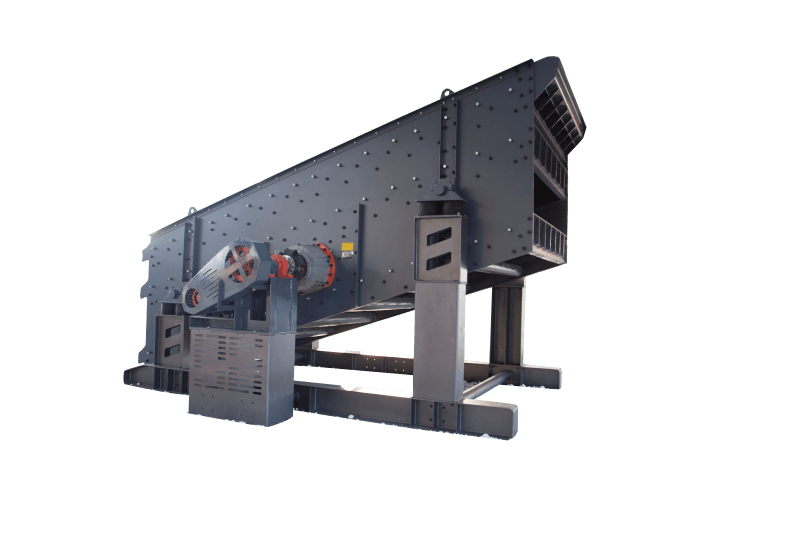

Screening and Separation

Screening classifies particles by size, directing oversize back for re-crushing and undersize to separation. Magnetic or gravity methods then isolate iron from gangue, recovering up to 95% of valuables.

Integration with Zenith S5X Series Vibrating Screens ensures accurate sizing with high frequency and dip angles for superior efficiency. Their simple structure minimizes downtime, supporting capacities over 500 TPH in wet or dry setups. This reduces maintenance by 20% in iron ore plants.

Grinding and Milling

Grinding pulverizes ore to fine sizes below 100 microns, enabling effective concentration via flotation or magnetic separation. This step consumes up to 50% of beneficiation energy, making efficiency critical.

Zenith LM Vertical Mills provide energy-saving grinding with capacities from 10-170 TPH, grinding iron ore to 600 mesh while cutting power use through roller-table design. Ideal for pelletizing feeds, they boost recovery rates in high-volume operations.

Zenith Crusher’s Role in Optimizing Iron Ore Operations

Zenith offers modular plants that combine jaw crushers, cone crushers, vibrating screens, and belt conveyors into flexible, mobile configurations. These plug-and-play systems scale from 100 TPH for small sites to over 1,000 TPH for mega-operations, ideal for relocating as deposits shift.

For iron ore, Zenith’s portable plants handle abrasive feeds with minimal foundation needs, enabling quick deployment. Customizable via AI-driven controls, they integrate seamlessly with existing fleets.

Key Benefits

Zenith equipment boosts throughput by 25-35% through optimized crushing ratios and automation, while cutting operational costs via durable components that extend wear life by 40%. Energy-efficient designs lower power draw, and built-in dust suppression—using water mist and enclosed hoppers—reduces emissions by up to 50%.

Case Studies

In Australia’s Pilbara region, a major iron ore mine deployed Zenith’s HPT Cone Crusher for secondary crushing, processing up to 2,000 TPH of hard hematite. Automation features enabled 24/7 operation, yielding 30% higher throughput and 25% lower energy use compared to legacy systems.

Another case: An Indian iron ore plant integrated Zenith’s mobile crushing line, reducing ore from 300 mm to 6 mm fines, boosting overall productivity by 35% and cutting transport costs by 20% through on-site processing. These gains, detailed in Zenith reports, highlight 20-40% efficiency uplifts across global sites.

Frequently Asked Questions (FAQs)

Q: What is iron ore and how is it primarily mined?

A: Iron ore is a mineral deposit rich in iron oxides like hematite and magnetite, formed through geological processes over billions of years in sedimentary or volcanic environments. It’s primarily mined via open-pit methods for shallow deposits, where overburden is removed and ore is blasted and excavated—accounting for over 95% of global production. Underground mining suits deeper sites.

Q: What are the key stages in the iron ore mining and processing process?

A: The process includes exploration, extraction (drilling, blasting, loading), primary crushing, beneficiation (secondary crushing, screening, grinding, and separation), and transport. Beneficiation upgrades low-grade ore (30-40% iron) to 65%+ concentrate for steelmaking. Zenith’s integrated systems, like PE Series Jaw Crushers, optimize these stages for higher yields.

Q: What equipment is best for crushing iron ore, and why?

A: Primary crushing uses jaw crushers for large boulders, while cone crushers handle secondary/tertiary stages for mineral liberation. Zenith’s CS Series Cone Crushers stand out, offering up to 30% energy savings and capacities over 500 TPH in abrasive conditions. Their robust design ensures minimal downtime.

Q: How does beneficiation improve iron ore quality, and what role do screens and mills play?

A: Beneficiation separates iron from impurities via crushing, screening, and grinding to achieve fine particles for pelletizing. Vibrating screens classify sizes accurately, and vertical mills grind to <100 microns efficiently. Zenith’s S5X Series Screens and LM Vertical Mills boost recovery by 20-30%, reducing waste.

Q: What are the environmental challenges in iron ore mining, and how can they be mitigated?

A: Challenges include dust emissions, water use, and land disruption, but modern practices recycle 70%+ of water and use dust suppression. Zenith’s equipment features enclosed designs and low-emission tech, cutting impacts by 40-50%. With 2025 regulations tightening, their modular plants support green mining.